Proliner in-situ curing repair waterproof hose successfully applied to water related environment restoration in Qingdao

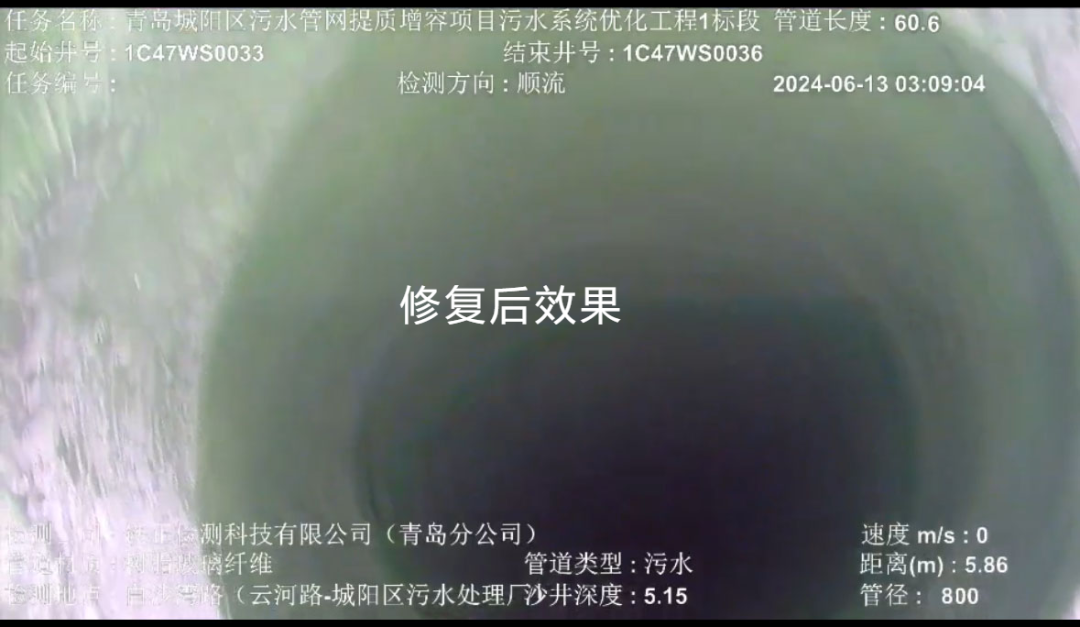

The Chengyang District Sewage Network Improvement and Capacity Expansion Project - Chengyang District Sewage System Optimization Project is located on Baishawan Road in Chengyang District, Qingdao City, Shandong Province. The pipeline network to be repaired is a DN800, 9mm sewage pipe with a total length of 60.6 meters.

Due to severe signs of aging in the sewage pipeline system in some areas of this road section. Problems such as damage and leakage are constantly emerging, which not only affect the normal operation of urban sewage drainage systems, but also pose potential pollution risks to the surrounding environment.

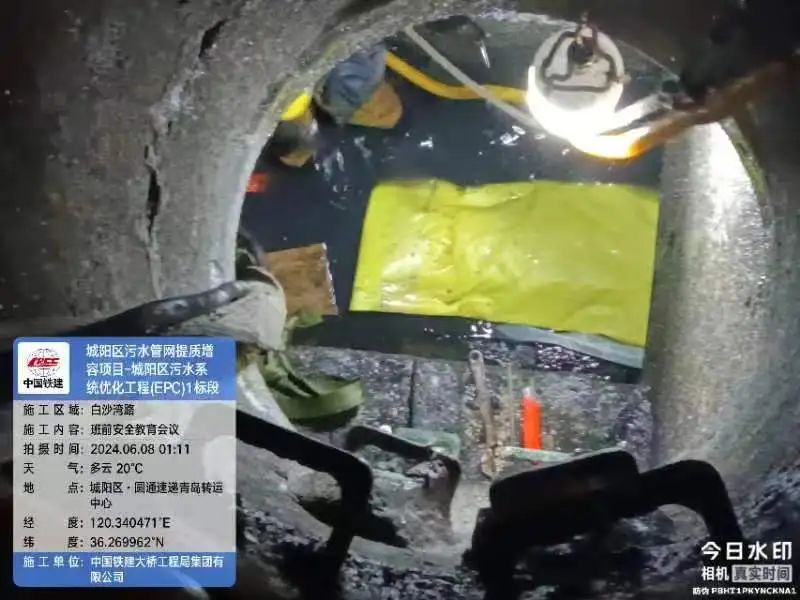

Traditional repair methods have drawbacks such as long construction periods and large impact areas, and the repaired road sections are narrow. In order to ensure the normal operation of social roads, Prolan, in conjunction with the construction unit of China Railway Construction Bridge Engineering Group Co., Ltd., has decided to adopt more advanced non excavation repair technology to solve this problem.

Repair Overview

Fix difficulties

The effect of water on UV in-situ curing inner lining hoses:

1. The influence of water on the cutting of lining hoses

When there is partial water accumulation or groundwater upwelling in the original pipeline, the bottom film enters the original pipeline and floats on the surface of the accumulated water, making it unable to adhere to the original pipeline. During the conventional UV in-situ curing process of lining the hose, it is easy to detach from the bottom film and rub against the original pipeline, resulting in material damage and water ingress.

2. The influence of water on the curing of lined hoses

The construction process of UV lined hose materials must strictly reject water. If the inner fiberglass resin impregnation layer comes into contact with water, the water and resin paste will undergo an emulsification reaction, resulting in whitening and a decrease in the mechanical properties of the cured lining tube.