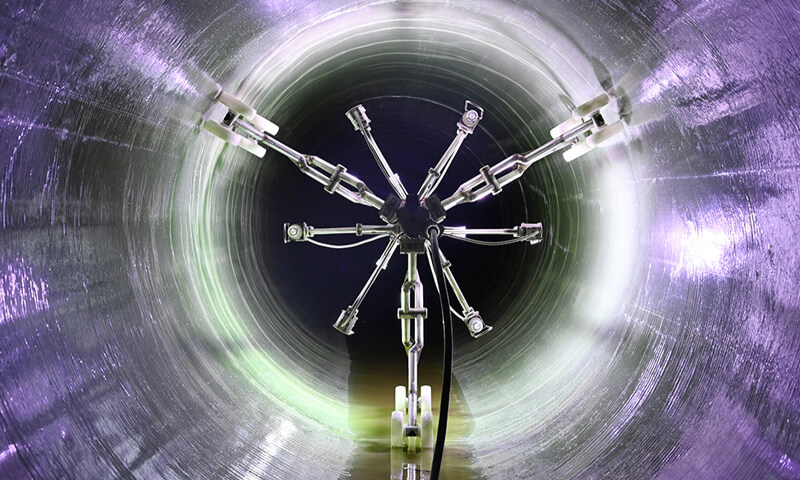

Localized repair of UV-CIPP hose

The locally repaired UV-CIPP lined hose consists of an inner membrane, a light cured glass fiber hose impregnation layer, a light cured adhesive, and an outer membrane from the inside out. UV cured adhesive can be applied in damp or slightly moist pipeline environments without affecting the curing effect of UV-CIPP. After the UV-CIPP lining hose is partially repaired, the original pipeline is tightly bonded to the lining tube through a one-time curing of the airbag. This not only achieves pressurized waterproofing, but also the repaired lining tube has the structural performance of UV-CIPP hose, which locally enhances the structural performance of the original pipeline.