UV curing repair of severely corroded pipelines in extremely cold regions at minus 23 ℃ for 5 hours

This project is located in Xiaogongzi Street, Daoli District, Harbin City, Heilongjiang Province. It is situated in an old residential area where pipeline damage and aging have always been a difficult problem to solve. Due to the cold weather, repair work has become extremely difficult, and traditional excavation based repair methods often cannot achieve optimal results in extreme environments.

Due to the construction site being located in the core area of Harbin city center in Heilongjiang province, surrounded by numerous schools and residents, with dense traffic and pedestrians,

Therefore, "non excavation repair" has become the best choice for this repair.

Repair Overview

Fix difficulties

1. The transportation of lined hoses must be carried out using insulated vehicles throughout the entire process.

2. The lined hose should be stored in a constant temperature warehouse at (5-25) ℃, and the material should not be exposed to a sub zero environment for a long time:

2.1 Low temperature construction temperature requirements for Proliner lined hoses: Exposure to -5 ℃ for no more than 2 hours. If the actual situation does not allow, insulation sheds or hot air equipment should be built to keep the materials warm and insulated;

2.2 It is recommended to prepare the relevant preparations before cutting the inner lining hose, quickly complete the cutting of the inner lining hose, and shorten the exposure time of the inner lining hose to extremely cold weather.

3. If the material is exposed to low temperature weather due to uncontrollable factors, it is recommended to insulate and wait inside the pipeline. The material will gradually warm up and become soft before tying the head.

4. When maintaining pressure, it is recommended to extend the holding time (beyond 30 minutes) and wait for the material to fully adhere to the pipe wall.

5. When lowering the bottom film, try to use insulation equipment as much as possible to avoid prolonged direct contact with low temperature weather. You can reduce the speed of pulling the bottom film to avoid breaking it.

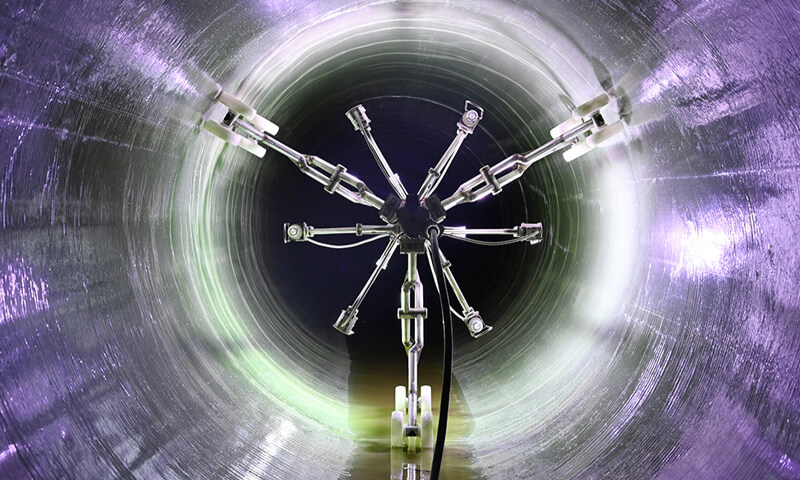

6. When starting to turn on the curing lamp for curing, it is recommended to reduce the curing speed and wait for the temperature to display a normal temperature before restoring the curing speed.