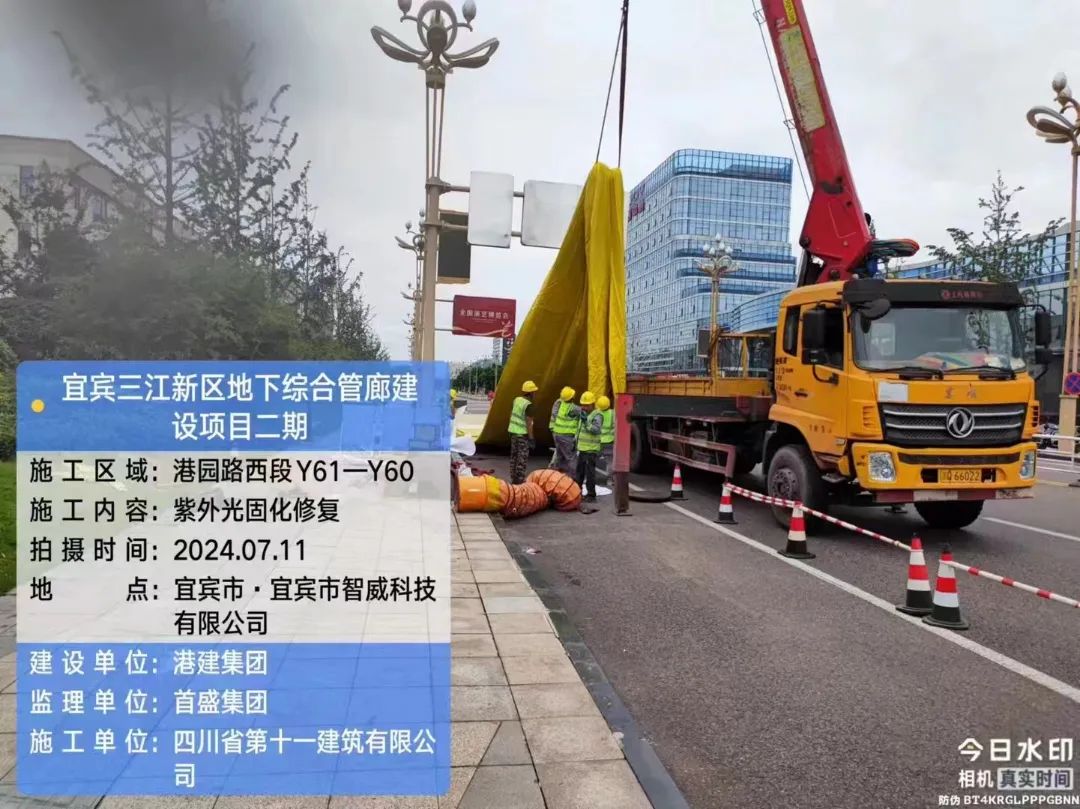

Proliner UV curing repair supports the Yibin project in Sichuan, breaking through the "three major mountains" of curing repair

Overview of the Second Phase of the Underground Comprehensive Pipe Gallery Construction Project in Sanjiang New Area, Yibin: UV-CPIPP, CIPP, spraying, grouting and other methods were used to repair and rectify the approximately 165 kilometer municipal rainwater and sewage pipe network within the scope of Sanjiang New Area, and to remove sediments, obstacles, etc.

The main roads involved include 53 municipal roads such as Changjiang North Road, Changcui Road, Daxue Road, Gangyuan Road West Section, and Jinghua Road.

Repair Overview

Fix difficulties

1. Long term high-temperature operation during solidification: In high-temperature environments, equipment may be at risk of overheating, damage, etc. Effective heat dissipation and protective measures need to be taken; Long term high-temperature operations may lead to increased equipment wear and tear, which increases the difficulty of curing.

2. Working in water related environments: Repair pipes with obvious flowing water. The Prolan UV cured repair lining hose enters the original pipe and floats on the surface of the accumulated water, making it unable to adhere to the original pipe. During the conventional UV in-situ curing lining hose cutting process, it is easy to detach from the bottom film and cause scratches with the original pipe, resulting in material damage and water ingress.

3. Large diameter repair: The construction section for pipeline repair is relatively complex, with some sections having large diameters of DN1000-1590.