Proliner technology demonstrates outstanding efficiency and provides strong support for the successful implementation of the DN2000 sewage pipeline repair project in Beipai

The DN2000 ultraviolet light pipeline in-situ curing repair project undertaken by Beipai Construction Company belongs to the pipeline renovation project of Gaobeidian Water Plant in Chaoyang District, Beijing.

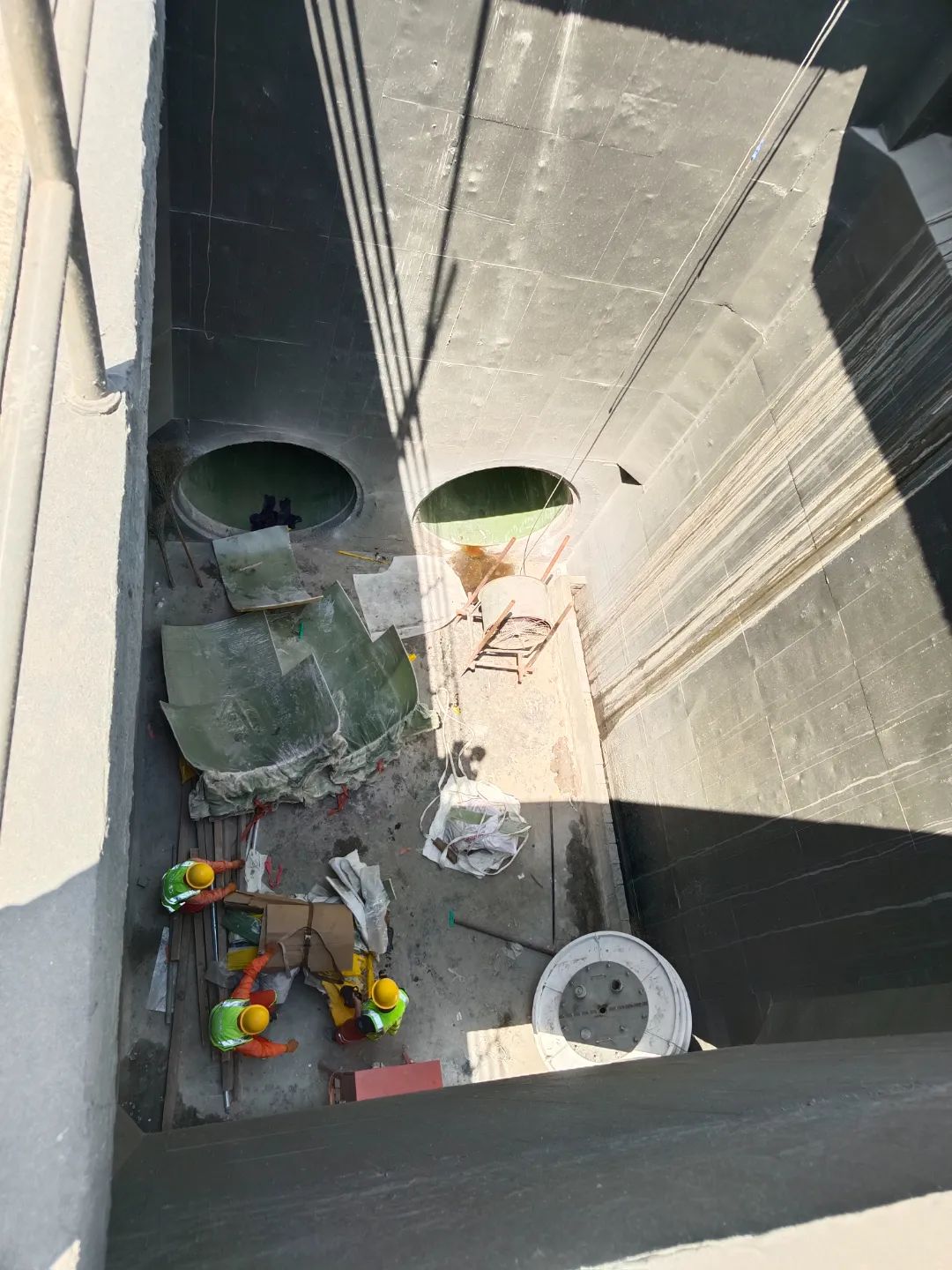

The project is located in the No.1 distribution pool of the first phase distribution well in Gaobeidian Water Plant. The pipeline network to be repaired is a DN2000 sewage pipe with a single section length of 184 meters, divided into two sections with a total length of 368 meters.

Repair Overview

Fix difficulties

1. Special location: Due to the unique geographical location of the project, it requires crossing rivers and multiple roads, making the project difficult and requiring extremely high requirements for materials and construction;

2. Project burial depth of 16 meters: The design elastic modulus of UV-CIPP UV cured hose material must be higher than 20000 MPa;

3. Large pipe diameter and thick material: Due to the heavy material of the lining hose of the large pipe diameter, it may cause material distortion when going down the well. If there is insufficient construction experience, it may result in curing failure;

4. Large wall thickness: The material with a large wall thickness of 12mm poses a dual challenge to production technology and on-site construction.

5. Strict requirements for UV lamps: The repair of DN2000 pipelines requires strict control over pressure holding and travel time, which poses a severe challenge to the durability and illumination of UV curing lamps.